Brewers Need Efficiency to Master Shifting Industry

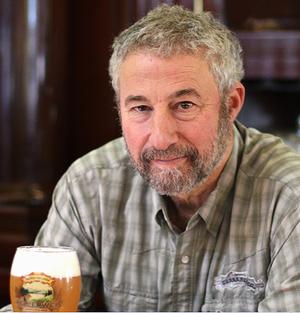

BRUSSELS, Belgium, May 26, 2023 (Maximpact.com Sustainability News) – A cold beer at the end of a hot day tastes mighty good. When most people enjoy a cold one, the energy efficiency and carbon footprint of the brewery that made the pint at their lips rarely crosses their minds. But that’s not true of Ken Grossman. Energy efficiency is top of mind for him.

Since he bottled the tiny company’s first Pale Ale in California in 1980, Grossman’s Sierra Nevada Brewing Company has grown into the third largest craft brewer in the United States, and the seventh largest beer producer in the country.

As founder and CEO of Sierra Nevada, Grossman now uses renewable resource technologies to offset the energy needed for production in the company’s two breweries, in California and across the country in North Carolina.

Sierra Nevada currently employs solar panels to supply 20 percent of its energy needs and hydrogen fuel cells that supply another 40 percent, generating electricity with zero global warming or air polluting emissions.

Conserving energy through efficiency measures is another top priority for Grossman that is top of mind as he manages Sierra Nevada.

The company reuses, recycles or composts more than 99 percent of its solid waste and has restructured its packaging system for optimal efficiency and green return. The brewery recycles carbon dioxide (CO2) for carbonation of the beer back into the brewery instead of purchasing the CO2 and shipping it to a brewery.

European Brewers Embrace Efficiency

Europe’s diminished beer industry, with 9,500+ breweries, down 500 after COVID-19, is optimistic about returning to its pre-pandemic heights in 2023, The Brewers of Europe Secretary General Pierre-Olivier Bergeron said in December at the ninth edition of the organization’s Beer Serves Europe event in Brussels.

Bergeron said the beer sector remains positive in its outlook as it recovers from the pandemic-induced lockdowns, despite rising energy costs and the more recent disruptions to key supply chains, including grain, glass and even the carbon dioxide needed for bottling.

Based in Brussels, The Brewers of Europe brings together national brewers’ associations from 29 European countries to support the united interests of Europe’s breweries.

The organization promotes “the positive role played by beer and the brewing sector in Europe and advocates the creation of the right conditions to allow brewers to continue to freely, cost-effectively and responsibly brew and market beer across Europe.”

Consumption has continued to evolve as Europe’s beer renaissance develops with increased innovation and growing choice for consumers, speakers said. For instance, at a recent event in Brussels, The Brewers of Europe served a selection of 40 different non-alcoholic beers, reflecting the growing diversity in this category where non-alcoholic beer now represents over five percent of the EU beer market.

While brewery numbers are no longer increasing at quite the same pace, with the closure of bars and restaurants during the pandemic taking its toll on the brewers, there are now an estimated 9,500 breweries operating in the European Union, innovating to meet consumer demand.

Even though the brewing sector faces challenges, brewers remain upbeat as they craft a sustainable future.

“The past three years have been challenging for all of us involved in brewing,” Bergeron said. “The multiple lockdowns put a lot of breweries at risk. However, I am confident that, as we recover and innovate, we will be able to grow again. Furthermore, we will do so sustainably, as we put in place more and more environmentally friendly practices.”

The Beer Serves Europe event last December was also an opportunity to consider important legislative action this year, including the Packaging and Packaging Waste Regulation.

Bergeron told the brewers that packaging their products sustainably is within reach.

“Leading by example, brewers have a core belief that whilst making beer, we can have a positive impact on the planet. We take our responsibility to limit the environmental impact of beer packaging throughout the lifecycle by reducing, reusing and recycling,” he said.

“We support the circular economy and the systems intended to ensure containers be returned and don’t go to landfill or end up as litter,” Bergeron said.

The European Commission aims to build a more climate-friendly Europe, in part, by creating a circular economy for packaging. The Commission aims to ensure that “all packaging in the EU is reusable or recyclable in an economically viable way by 2030,” in line with the EU Green Deal and the EU Circular Economy Action Plan.

So, the European Commission is renewing the EU Packaging and Packaging Waste Regulation with a proposal <https://environment.ec.europa.eu/publications/proposal-packaging-and-packaging-waste_en> published on November 30, 2022.

The proposed regulation defines the essential requirements for packaging design and composition and sets out packaging collection and recycling targets. It aims to improve the environmental performance of packaging, reduce packaging waste and protect the free circulation of packaging in the EU Single Market.

It addresses three groups of interlinked problems, defined as:

1. growing generation of packaging waste linked to an increase of single-use packaging, a high level of avoidable packaging, and a bigger share in plastics within the packaging mix.

2. barriers to packaging circularity, especially an increased use of packaging design features that inhibit recycling and confusing labelling of packaging for consumer sorting. Further, fragmented markets prevent cost-efficient waste management in an internal market.

3. downcycling and the low levels of uptake of recycled content in packaging, which limits the EU’s ability to reduce the use of virgin materials in new packaging.

Status of Proposed Packaging Regulation

To date, the draft law is still being discussed in Parliament and in the Council. Once these institutions have adopted their negotiating mandate, inter-institutional negotiations will begin before official adoption. Environment Commissioner Virginijus Sinkevičius has stressed how important it is for co-legislators to reach an agreement ahead of the European elections of May 2024.

In the Council, discussions are ongoing at the technical level. At political level, representatives of the Member States welcomed the Commission’s ambition to reduce packaging waste, but they did express some concerns.

In Parliament, the Environment Committee is leading the work , while Industry, Internal Market, and Agriculture Committees will give their opinions; the discussion between the political groups to find agreements is beginning.

European Parliament Beer Club Likes Sustainable Packaging

MEP Ivan Štefanec, president of the European Parliament Beer Club, hosted a timely policy debate on the issue March 8, when he welcomed three key representatives selected from a wide range of stakeholders:

* – Aurel Ciobanu-Dordea, director for circular economy DG ENV, European Commission

* – Franc Bogovič, vice chair, European Parliament’s Intergroup on Climate Change

* – Cor Waringa from The Brewers of Europe, a nonprofit organisation that represents 29 national brewers’ associations to the European Union

Waringa enthused about the power of the beer sector’s commitment to sustainable packaging through reuse and recycling to encourage European brewers to adopt a modern, more efficient approach that benefits the society as a whole and the individual brewers themselves.

“Our strength is our diversity,” Waringa said during the discussion. “There are 80 styles, 50,000 brands and 10,000 breweries in Europe. Every brewer has a tremendous power to drive change, and to be part of the transition to sustainable society. We are leading by example in the sustainability area.”

Ciobanu-Dordea recognised that brewers are pioneers in recycling and reuse, saying, “I encourage the beer sector to remain champions of sustainability.” But he left the door open to amend provisions in the proposal.

As Secretary General of The Brewers of Europe, Bergeron, describing the debate in an opinion piece in Euractive March 16, wrote, “While meeting targets and obligations will be a challenge and we will need time for necessary adaptations, the brewing sector’s commitment to a sustainable future for beer is real. We recognise our responsibility to continue to deliver, within a good functioning EU Single Market and an ambitious EU-wide environmental sustainability agenda, including for packaging and packaging waste.”

But the brewers feel the proposed regulation discriminates against them, Bergeron explained.

“For all the noble aims of the PPWR proposals, there are elements in the draft that are problematic. Some brewers, both big and small, would have to create new packaging lines purely to meet targets, even if the environmental cost was not justified. Well-functioning systems are not being ringfenced from the impact of one-size-fits all solutions proposed in the EU Regulation,” Bergeron wrote.

“Brewers, for the simple reason they are leaders in packaging sustainability, are being discriminated against versus their closest competitors on the market.”

“It is crucial therefore that appropriate transition periods, of on average five years, kick in not just after adoption of primary legislation but also after each implementing act, many of which will determine exactly how each operator needs to adjust its business to deliver on the objectives,” Bergeron wrote on behalf of European brewers. “We expect these to be amongst the issues MEPs and ministers continue to discuss when they debate the PPWR, including in the Environment Council.”

Many New Technologies Available

Breweries are expected to increasingly embrace the Internet of Things (IoT) in the future, using technology such as RDIF tagging, radio-frequency identification that uses smart barcodes to identify and track tags attached to objects; GPS shipment tracking; programmable logic controllers; and sensors to automate beer production.

Today, beer brewers no longer have to guess what’s happening inside their fermentation tanks. They can view all active fermentations, from multiple locations, in a single dashboard, manage their settings, and get problem alerts by email and text.

The Internet of Things is transforming the brewery processing system with automation on all levels. The technology is transforming the beer industry across the world with sensor-based solutions, automated processing, interconnected assets, a data-driven approach, and more accurate decision making.

IoT-based sensors collect data and process information on a user’s smart gadget by triggering the required notifications. Managers can automate the entire process with a click, which saves their time and energy and improves the overall efficiency of the plant, the Florida-based company Biz Intellia explains. “It is enabling the industrialists to enhance the business productivity by taking informed decisions, which directly impact the growth of their business.”

Maximpact Can Help

So, the beer brewing industry is in constant flux. Brewery owners and managers must stay on top of all changes, while constantly working toward greater sustainability and energy efficiency. Maximpact’s efficiency experts can help. Contact Maximpact through this website 24/7.